Liquid And Lyophilised Product Vial Filling Line

Salient Features:

| Utilities: | Models |

|---|---|

| Inlet Compressed air Pressure Required: 5kg/cm² | Ampoule Washing Machine |

| AWM - 60Ampoules / Minutes | |

| AWM - 120Ampoules / Minutes | |

| Inlet Purified Water Pressure Required :3.5kg/cm² | AWM - 200Ampoules / Minutes |

| AWM - 300Ampoules / Minutes | |

| Inlet WFI Water Pressure Required :3.5kg/cm² | Vial Washing Machine |

| VWM – 60 Vials / Minutes | |

| B. Electrical Voltage: 380V/415V,3Phase,50Hz | VWM – 120 Vials / Minutes |

| VWM - 200 Vials / Minutes | |

| VWM - 300 Vials / Minutes | |

| Output for 2ml Vial/Ampoules |

Salient Features:

| Technical Data | Models |

|---|---|

| Electrical Voltage: 380V/415V,3Phase,50Hz | HST-300 : 320Ampoules/Minute |

| Power Consumption: 45Kw to 110Kw | HST-400 : 400 Ampoules/Minutes |

| Air Consumption: 2000CMH to 9000CMH | Vial Sterilizing Tunnel |

| HST-400 : 180 Vials/Minutes | |

| HST-600 : 400 Vials/Minutes | |

| HST-900 : 600 Vials/Minutes | |

| Output for 2ml Vial/Ampoules |

Salient Features:

| Technical Data | Models |

|---|---|

| A.Electrical Voltage: 380V/415V,3Phase,50Hz | VFB-4HD : 120Vials/Min |

| VFB-6HD : 200Vials/Min | |

| B.Power Consumption: 5 Kw to 7.5Kw | VFB-8HD : 300Vials/Min |

| C.Nitrogen Pressure required :1Kg/cm² | |

| Output for 2ml Vial |

Salient Features:

| Technical Data | Models |

|---|---|

| A.Electrical Voltage: 380V/415V,3Phase,50Hz | RVCM -4HD : 100Vials/Min |

| RVCM-8HD : 150Vials/Min | |

| B.Power Consumption:3Kw to 5.0Kw | RVCM-12HD : 300Vials/Min |

| Output for 2ml Vial |

Salient Features:

Application:

Features:

Sterilization by dry heat has become increasingly popular worldwide due to two reasons first the need to sterilize small objects, particularly ampoules, syringes and secondly for de-pyrogenation of manufacturing apparatus which is not possible in a steam sterilizer. Another advantage of this method of sterilization is that objects which are damaged by water or steam e.g. powder or ointment can be sterilized provided the heat penetrates to all parts of the substance.

Applictions:

Features:

The principle that terminal sterilization provides a higher degree of sterility assurance than aseptic processing is well understood and leads regulatory agencies around the world to require that if the product can be terminally sterilized it must be. The technology of hot water sterilization with counter pressure has been developed specifically for the terminal treatment of solutions in sealed containers.

Applictions:

Features:

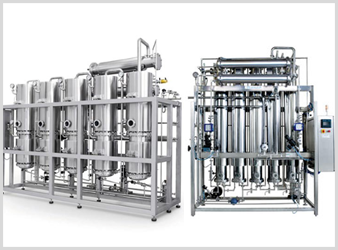

All pharmaceutical production processes require a stable & consistent supply of quality controlled water for applications ranging from non-critical processes to product formulation. The most important equipment in any pharmaceutical plant manufacturing injectable solutions is the WFI Still. Our WFI Still produces distillate that meets the current U.S and European pharmacopeia for Water for Injection guidelines systems equipped with a range of features to ensure that your installation and qualification is quick & trouble-tree and that your WFI production remains efficient and reliable.

Features:

The sterilization process at a pharmaceutical industry requires high quality pure steam with accurate pressure control and fast response times. Pure Steam Generator is capable of producing pyrogen-free sterile pure steam that when condensed meets all USP requirements for use in steam sterilizers, critical area humidification and routine SIP.

Features:

The WFI Still work on the distillation principle. The first column is heated by the external Plant steam. The generated vapor by the feed water rises up the column where it is subjected to the entrainment separation system. Multidirectional baffles deliver the first punch. The steam generated from the first column is made to pass a torturous path through multidirectional baffles. Here the pyrogen particles and droplets separate and are guided to the end of the column.

A centrifugal type cyclone separator high up in the column delivers the second punch. Here the vapor is guided through a narrow circular channel where it begins to rotate. The vapor flow subjects the pyrogenic impurities and droplets to a high centrifugal force thereby dislodging them from the vapor steam. The distillation units are connected in series into a multiple effect system and external energy is required only at the first column. The steam generated in each column is supplied to the subsequent column.

The generated steam vapor of the last column and the almost condensed steam distillate (2nd column onward) is led to the over head cooling heat exchanger, where it is cooled by the cooling water & incoming feed water to generate WFI.

Features:

After the purification of PW or HPW, engineering of the customer-specific storage and distribution system takes place, so product water can be delivered to each point of use in the sterile distribution system without recontamination. Here to we consider the customer's specific conditions and produce an individually engineered design.

Features:

Product Highlights:

Salient Features:

Key Specifications:

Product Highlights:

Salient Features:

Key Specifications:

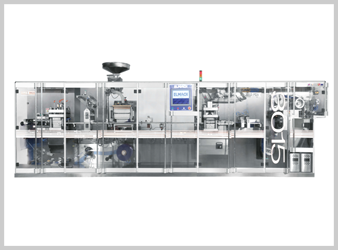

SALIENT FEATURES:

OPTIONAL FEATURES:

FEATURES

TECHNICAL SPECIFICATIONS:

|

MODEL |

EPI-3015 PDA |

|

Max. Blister Forming Area |

300 mm web width X 166 mm advance |

|

Max. Forming Depth |

12 mm |

|

Base Film |

Roll core diameter 72-76 mm |

|

Lidding Foil |

Roll core diameter 72-76 mm |

|

Speed |

Max. 50 cycles/min |

UTILITIES REQUIRMENTS:

|

Power Supply |

415 V/50 Hz |

|

Connected Load |

Peak 21 KW, Average 16 KW |

|

Compressed Air |

450 NLPM 5 kg/cm2 |

|

Chilled Water |

200 lph @ 3 kg/cm2 |

|

Weight |

3,000 kg approx. |

It is recommended that the machine is installed in air conditioned premises having room temperature of 22 0c to 26 0c to ensure efficient working” note: specifications are indicative and we reserve the right to modify them without prior notice.

TECHNICAL SPECIFICATIONS:

|

MODEL |

EPI-MINI (MODIFIED) |

|

FORMING MATERIAL |

THERMO FORMING PVC, PVC WITH PE/PVC, COC, ACLAR COLD FORMING TRLLAMINATED ALUMINUM FOIL |

|

LIDDING FOILS |

HARD TEMPERED ALUMINUM, MEDICAL GRADE PAPER |

|

REEL SIZE |

BASE FILM 440MM DIA X 350MM WIDTH LID FOIL 250MM DIA X 350MM WIDTH |

|

SPEED |

UPTO 40 CYCLES PER MINUTE |

|

PUNCH CYCLE |

UPTO 160 CUTS PER MINUTE |

|

OUTPUT |

UPTO 750 BLISTERS PER MINUTE DEPENDING ON FORMAT AND PRODUCT |

|

BLISTER DIMENSION |

WIDTH 30-100 MM |

|

PRODUCT FEEDING |

SYNCHRONISED FEEDER WITH STANDARD FEEDING CHANNEL |

UTILITIES:

OPTIONAL FEATURES:

SALIENT FEATURES:

SHIPPING DIMENSIONS FOR BASIC MACHINE:

|

DIMENSIONS |

NET WT. |

GR. WT. |

|

241" x 61" x 83” |

390 0 kg. |

4500 kg |

It is recommended that the machine is installed in air conditioned premises having room temperature of 22 0c to 26 0c to ensure efficient working” note: specifications are indicative and we reserve the right to modify them without prior notice.

TECHNICAL SPECIFICATIONS:

|

MACHINE SPEED |

(CARTON/MIN.) |

UPTO 100/MIN. |

|

CARTONS |

MIN. SIZE (A X B X H) |

30 X 30 X 70 |

|

LEAFLETS |

MIN. FORMAT (mm) |

100 X 80 |

|

UTILITIES |

CONNECTED LOAD (KW) |

4 |

|

FLOOR SPACE INCLUDING MAGAZINE AND LEAFLET FOLDER |

MACHINE WIDTH (mm) |

1580 |

|

NET WEIGHT |

(KG) |

APPROX. 1400 |

SHIPPING DIMENSIONS FOR BASIC MACHINE:

|

DIMENSIONS |

NET WT. |

GR. WT. |

|

126" x 666" x 76" |

1400 kg |

1800 kg |

It is recommended that the machine is installed in air conditioned premises having room temperature of 22 0c to 26 0c to ensure efficient working” note: specifications are indicative and we reserve the right to modify them without prior notice.

Plain or printed laminated aluminum foil for strip pack - These soft aluminum foils are suitable for strip packaging of Pharmaceutical products such as tablets, capsules, etc.

They are manufactured in different gauges with most common being 25µ/30µ/40µ for pharmaceutical applications. The foils have LDPE Laminated on one side & other side is printed. Aluminum Strip Foils can be made available in various sizes and specifications as per our customer's requirement.

Plain or printed aluminum foils for blister packs are used mostly in the pharmaceutical industry to package tablets and capsules in a manner that they remain protected from ambient contamination. These are hard aluminum foils where one side is coated with heat seal lacquer and the other side is unprinted or printed to facilitate pharmaceutical blister packaging. Most common foil thicknesses used in pharmaceutical blister packaging are those of 20µ/25µ/30µ. The heat seal lacquer is a colorless vinyl resin conforming to the applicable international regulations for pharmaceutical applications. This is suitable for heat sealing to PVC/PVDC coated PVC films. The range of this can vary from 4gsm -8gsm depending on the speed, product and packaging.

Aluminum Collapsible tubes find application in the multinational pharmaceutical and cosmetic companies to whom we are major suppliers.

Their applications include:

Advantages of Aluminum Collapsible Tubes

Tamper proof - Cannot be refilled or reused Protection of Contents - Contents are safely protected from any contamination Non-Toxic & Hygienic: Aluminum Collapsible tubes are non-toxic, hygienic, non-absorbent and Impart no taste, flavor, odour or color to contents inside Ease of Movement - Being light weight they are easy to handle and transport reducing end product costAluminum Collapsible Tube Diameters (mm)

12.7 / 13.5 / 16 / 19 / 22 / 25 / 27.5 / 30 / 35 / 53

Laminated tubes are used for packaging across the globe in varied sectors such as cosmetics, pharmaceuticals, food and oral hygiene.

We use state of the art Euro machines to manufacture these tubes in line with international standards and specifications

Flexible Packaging material consists of a construction of material made from flexible substrates. These rolls are used to pack wide range of food items and consumer goods like detergents, shampoo etc. The packaging consists of one printable material, a barrier material and a sealant layer. The flexible packaging material can be supplied in the Roll form or Pouch form.

Laminated rolls are produced with rotogravure printing as well as clear and smooth lamination that are available in captivating designs and patterns and can also be custom made in various designs, sizes and volumes as per client's specific requirement. These rolls are moisture resistant and resist contamination of products.

Printable Material

Sealant layer

A Flexible Pack Offers the Following Advantages :

Flexible laminates are used for the packaging of following products :

Glass Bottles for Pharmaceutical Industry

Inject able/Antibiotic Vials for Pharmaceutical Industry

Our Serum Closure Range offers widest variety and blends in RHS (Ready for Sterilization) and RFU (Ready for USE) formats.

Products Registered with Type 3 US DMF (Drug MAster File), USA Products complying to ISO Standards : ISO - 8871, ISO - 8536 - 2, ISO - 8362 -2 and ISO - 8362-5

All Poducts also available as RFS (Ready for Sterilization) and RFU (Ready for use) Available in sizes - 13mm, 20mm, 25mm, 28mm, 32mm

Available in butyl, bromo-butyl, chloro-butyl, silicon, neoprene, nitrile and natural polymers Colors - Grey, Brown, Black, Blue and various other pharma code colors

The flip off seal comprises of aluminium seal and a plastic button attached to it. When the button is opened the aluminium seal crimped to rubber stopper tears leaving the injection area open.

SPECIFICATION:

Size :- 13mm and 20mm

Colour :- Red, Blue, Green, Yellow, Orange

( Colours can be made available as per customer requirement )

USFDA DMF Approved And an ISO 9001 certified manufacturer and exporter of ROPP caps ,Flip off and tear off SEALS for Pharmaceuticals, Beverages and Food Processing Industries.

StandardLine – designed to deliver reliable performance

The StandardLine includes:

High-quality syringe barrels are produced on fully automated, high-speed precision forming lines. Rigorous product inspection and strict process control is ensured by state-of-the-art camera inspection for both dimensional and cosmetic aspects.

Accessories

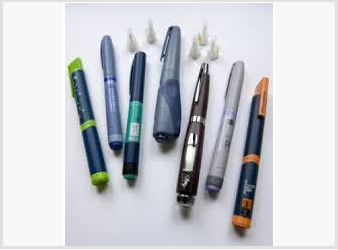

Insulin pens are growing in popularity, and many people with diabetes nowadays use a pen to administer insulin.

The pens allow more simple, accurate, and convenient delivery than using a vial and syringe. Not every person with diabetes will need to take insulin. However, those that do sometimes find that sticking to an insulin schedule can be demanding, disruptive, and draining. Some people prefer insulin pens as a way to make taking insulin less intrusive and inconvenient.

In this article, we look at the types of insulin pen, how to use them, and the benefits and disadvantages of choosing an insulin pen over a vial and syringe.

Types

Our disposable insulin pen is a prefilled and disposable, variable dose injection device designed for use with a standard 3ml cartridge, it is used for the injection of Insulin, Human Growth Hormone and other multidose therapies. This disposable insulin pen features an attractive design and high variability for customization and choice of color.

Product Features:

Specification:

|

Min. Dose |

1 iu (0.01ml) |

Max. Dose |

60 iu (0.60ml) |

|

Dose Accuracy Error |

≦ 5%, comply with ISO 11608-1 standard |

||

|

Main Container |

Standard 3 ml cartridge according to ISO 11608-3 |

||

|

Compatible Needle type |

Compatible with standard and safety pen needles according to ISO 11608-2 |

||

|

Certification |

CE Certificate and EN ISO 13485:2016 issued by TUV SÜD |

||

|

Application |

Diabets (Insulin), HGH (Human Growth Hormone), antibiotics, interferon, beauty products, biochemical emergency prevention, detoxification, antipyretic analgesic, Anesthetic sedative class, etc. |

||

The VanSea® Reusable Insulin Pen is a reusable, variable dose injection device designed for use with a standard 3ml cartridge, it is used for the injection of Insulin, Human Growth Hormone and other multidose therapies

Product Features

Specification:

|

Categories |

Reusable Insulin Pen |

Classification |

Reusable |

|

Model No. |

WH-RA1 |

Brand Name |

VanSea |

|

Material |

Brass |

Product Size: |

Φ17.8mm x 163mm |

|

Weight |

58g (exclude cartridge & needle) |

||

|

Min. Dose |

1 iu (0.01ml) |

Max. Dose |

60 iu (0.60ml) |

|

Dose Accuracy Error |

≦ 5%, comply with ISO 11608-1 standard |

||

|

Main Container |

Standard 3 ml cartridge according to ISO 11608-3 |

||

|

Compatible Needle type |

Compatible with standard and safety pen needles according to ISO 11608-2 |

||

|

Certification |

CE Certificate and EN ISO 13485:2016 issued by TUV SÜD |

||

|

Application |

Diabets(Insulin), HGH(Human Growth Hormone), antibiotics, interferon, beauty products, biochemical emergency prevention, detoxification, antipyretic analgesic, Anesthetic sedative class, etc. |

||